1989

Vanaf 1989 sorteerden we op ons bedrijf om ook noodvrachten voor Farm Frites te leveren. We startten met een 30 ton Bijlsma Hercules sorteermachine met drie zeefdekken. In het begin gebruikten we duobanden en een hallenvuller in een losse opstelling.

1994

We kopen de oude bunkers van de Farm Frites fabriek in Lommel. We bouwen de Bijlsma Hercules sorteerder in een vaste opstelling met vijf bunkers van elk 60 ton. De capaciteit was ongeveer 50 ton per uur en we sorteerden in drie maten.

2000

We gebruiken nog dezelfde installatie, maar met de stortbak als voorsorteerder. Zo verhogen we de capaciteit naar ongeveer 60 ton per uur. De bovenmaat werd gebypasst via de Miedema hallenvuller, zodat alleen de ondermaten over de Bijlsma Hercules sorteerder gaan.

2007

Na de brand in de nieuwe opslagloods besloten we een nieuwe sorteerderij te bouwen in de te renoveren schuur. Immers hadden we nu de kans om de sorteerderij in de nieuwe constructie te integreren. We stapten af van stalen bunkers en kozen voor grotere betonnen bunkers die met de verreiker kunnen worden geleegd. Op de 5 betonnen bunkers plaatsten we twee Campfens sorteerders. Dit deden we samen met collega-boeren en vier verreikers. We bouwden een verbindingsbrug tussen de nieuwe en oude bewaarplaatsen. Via een transportband op deze brug kunnen we de aardappelen naar de sorteerderij brengen. We laden de aardappelen via de stortbak en hallenvuller op de band om de installatie te vullen.

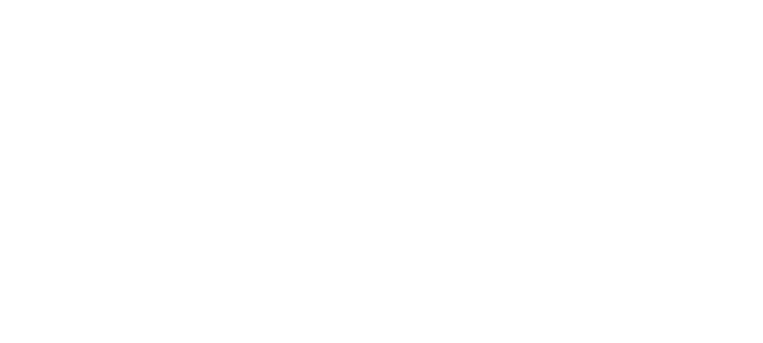

Daarnaast kochten we een wasser, bestaande uit een dubbele ontsteenmachine gevolgd door een wastrommel. Deze machines werden door Tummers geplaatst. In onderstaande 3D-tekening zie je de ontstener en de wasser.

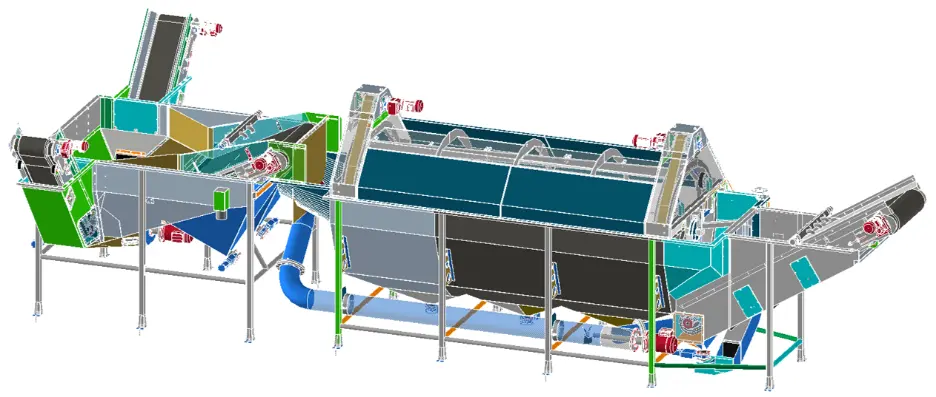

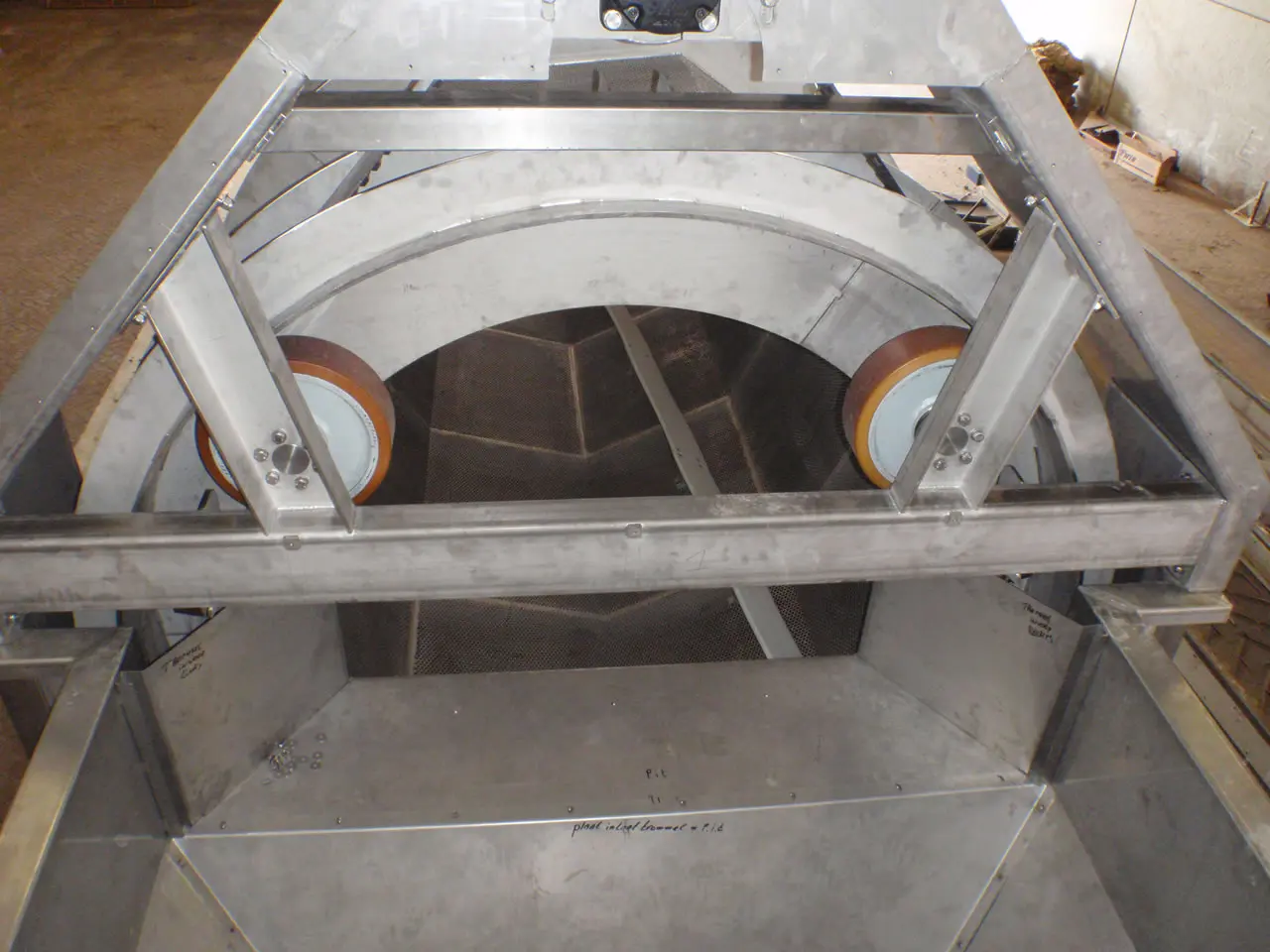

D.T. Dijkstra bouwde de installatie (behalve de Campfens sorteermachines) in samenwerking met Tolsma en Van den Borne Michelbrink voor de elektra-aansluiting. Hieronder zie je de installatie in aanbouw.

2008

In januari was het zover: de installatie is klaar. We begonnen met het wassen en sorteren van de aardappelen. De Manitou verreiker schepte de aardappelen uit de opslag en kiepte ze in de stortbak. Hier werd de meeste grond verwijderd met Ellips-rollen. Vervolgens werden de aardappelen met de hallenvuller naar de sorteerderij getransporteerd. De tweede grondreiniging vond plaats met stalen rollen die de aardappelen over een brede egelmat verdeelden. De mat verwijderde het loof.

Daarna gingen de aardappelen naar twee sorteermachines. Deze sorteerden de aardappelen in vier maten. Drie maten werden direct in de betonnen bunkers opgeslagen. De maat voor levering werd naar de wasser getransporteerd, waar de stenen werden verwijderd. De aardappelen werden gewassen in de trommel en daarna gedroogd met een lappendroger.

Na het drogen werden de aardappelen naar de verlaadbanden gebracht, die de vrachtwagens automatisch vulden. De capaciteit van de installatie was 140 ton per uur input. Ongeveer 90 ton per uur werd gewassen en gedroogd. Bekijk de werking in de onderstaande video.

Na het laden werden de aardappelen naar de fabriek vervoerd met de trekker, zoals je hieronder kunt zien.

2009

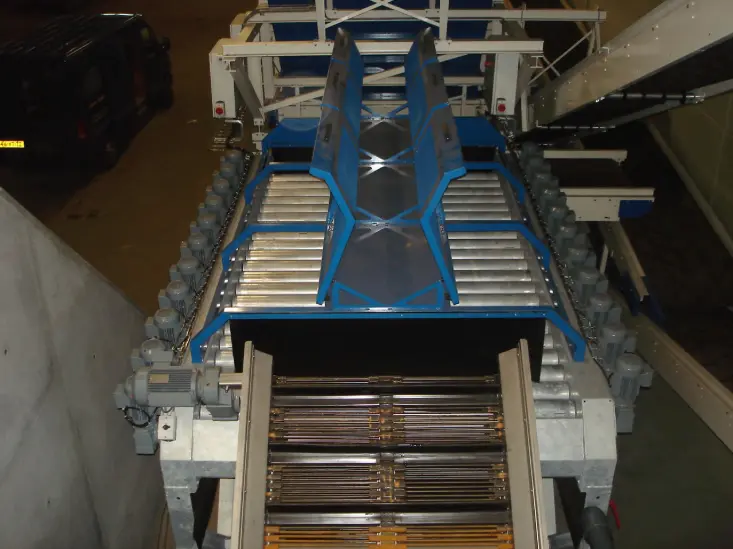

We besloten de oude wasser en ontstener in te ruilen voor een nieuwe machine met betere reiniging en meer capaciteit. De oude machine werd gereinigd en vervolgens met een verreiker en heftruck op een dieplader gezet. Daarna ging deze naar de nieuwe eigenaar. De ruimte waar de machines stonden werd goed schoongemaakt. Er was nu meer ruimte om de bestaande lopende banden aan te passen aan de nieuwe situatie.

De nieuwe machine arriveerde in onderdelen, omdat deze veel groter was dan de oude. De eerste vracht bevatte het chassis, dat meer dan 60 kuub water kan bevatten in bedrijf. De tweede vracht bestond uit de trommel met een diameter van 2,5 meter, plus andere componenten zoals trommellageringen en spijlenbanden. De montage van de machine duurde twee dagen. Het plaatsen en aansluiten van de onderdelen nam nog een week in beslag.

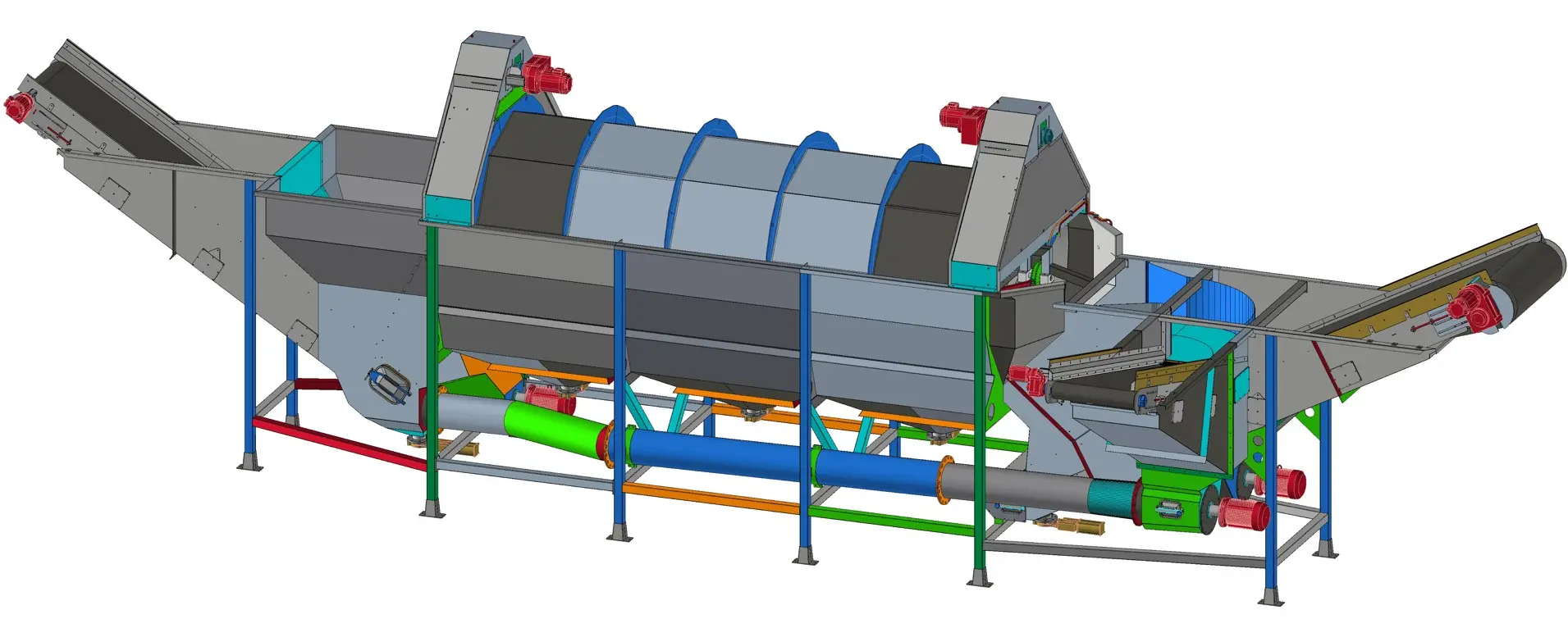

De nieuwe installatie is volledig geïntegreerd. Hij bevat kluiten- en stenen scheiders, en drijvende delen. In de 3D-tekening zie je de onderdelen: de ontstener is rood, de wastrommel geel, de uitdraaiband groen en de drijvende delen scheider blauw. We hebben de machine getest op een perceel met veel kluiten. De machine werkte goed en de aardappelen werden gewassen en geleverd. Na de test hebben we de machine verder afgesteld. Bekijk hieronder de video voor het proces vanuit de bewaarschuur tot in de vrachtauto.