2010

In 2010 we established the 'Making sense' partnership. We have established this partnership between WUR, TTW, BLGG and van den Borne potatoes to collect as much data from a test plot as possible and then combine it to form fertilization formulas based on precision agricultural data. In 2010, close sensing sensors were tested on the test field for a whole season. The Fritzmeier, Yara, Agleader and Greenseeker sensors are mounted on our sprayer. This data has been compared and we have concluded that it is best to use the Fritzmeier sensor for potato cultivation.

In 2010 we also started building the intermediate barn, the covering between the old storage. With the construction of the roof, it became possible to get the phytobac and the charging station covered. We have also expanded the potato storage by 5,000 tons. This is a building with three compartments. We also added a salt / clay bath to our laundry in the autumn. This allows us to sort glassy potatoes, which are potatoes with very little dry matter. We also started spreading compost on our plots in 2010. This allows us to retain more water in our soils, which provides a buffer to our potatoes in dry periods.

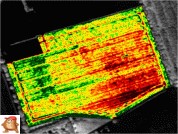

In order to further optimize cultivation, we also started in 2010 with a yield measurement on potato harvester. This allows us to map the results of parcels.

The yield meter was developed in collaboration with Probotiq. In this way, the yield of potatoes per field could be monitored in real time.

2011

In 2011 we started with our first soil scan. Orbit has made an initial scan of the home plot with the Dual-em. Orbit is a department of Gent University. Early in the season, with plants. We invested in a row fertilizer on the planter. This allows us to apply variable manure in every row.

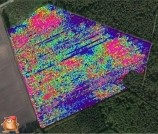

Flying with UAVs has also been started to collect data from plots during the growing season. This was done in collaboration with Aurea Imaging. As a result, recordings have been made at the company for a series of the VPRO "Netherlands from above". This episode of Nederland van Boven examines how farmers are constantly optimizing their land and how each special solution in the landscape creates a new question or problem.

At the end of the season, three new dump trucks have arrived. The Krampe Big Body 900 tippers are on three axles and can load 24 tons. By distributing the weight over three axles, we have an axle pressure of less than 8.5 tons per axle.

In 2011, Van den Borne invested in a phytobac to deal with chemistry in a sustainable manner. The phytobac ensures sustainable degradation of plant protection products that come from the sprayer. The phytobac is a completely closed system with no residual water. Because the filling and washing area is completely insulated, the amount of rinse water cannot be increased by rainwater. The rinsing and cleaning water is collected centrally and is pumped to a storage location. From here it is frequently sprayed over the phytobac. Because this system is fully automated, the amount of liquid sprayed over the phytobac is matched with the evaporation rate. A transparent roof is mounted on the phytobac. This roof is 50 centimeters above the substrate to obtain optimal air circulation and evaporation. The phytobac is placed in the sun and on the wind. These factors increase the evaporation capacity of the phytobac.

2012

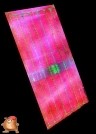

In 2012 we purchased our own soil scanner. The EM-38MKII, in combination with our Kubota RTV, is an indispensable part of our company. With the EM-38MKII we measure our plots before planting. Then we create a number of management zones based on this data. We use the created zones during the growing season to achieve an optimal cultivation return.

Since 2012 we have been driving a Dammann tandem sprayer with 2 tanks (10000 liters and 2000 liters) for variable crop protection and foliar fertilization at section level. Six Fritzmeier Isaria sensors are also mounted on the syringe to scan the crops.

Since 2012, the Isaria sensors have also been used to spread fertilizer. By placing two sensors on the tractor, the computer can adjust the amount of fertilizer in real time. As a result, we provide more or less fertilizer where necessary. This way we can save costs and we place less burden on the environment.

International Maas Prijs 2012

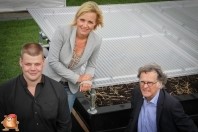

In 2012, we and our company were nominated for the international mesh price. Thanks to a unique collaboration, 100 farmers and contractors with new techniques have considerably reduced the burden on the Maas with plant protection products. This is important because the Maas is a source of drinking water. As a token of appreciation, Yvon Jaspers presented the prestigious International Maasprijs from RIWA-Maas to arable farmer Van den Borne potatoes from Reusel. "You know how to approach and are far too modest," said Yvon Jaspers, who was impressed by the performance of the farmers from the Meuse river basin. The farmers' investment in the new techniques results in a usage reduction of 5-70% and a drift reduction of 55-99%, which means that much less substance is released into the water. We were nominated for this because we have built a phytobak in which our remnants of spray agents are broken down. This environmentally-friendly investment has meant that we have also won the international mesh price!

Open door day 2012

Furthermore, in 2012 there was an open door day for all interested parties. On Saturday November 10, 2012 we held an open door day in honor of the royal visit of Queen Beatrix. On this open day, all machines and buildings could be visited and guided tours were provided. They were able to take a look in the kitchen with us. This has also been gratefully used, as a company we are very happy with it.

Visit Queen 2012

The highlight of 2012 is surely the visit of Her Majesty the Queen. Queen Beatrix visited our company on November 9. She took a tour with our whole family. She has had an explanation of the applications as we use them with all our machines. Jacob then gave a short presentation about the precision farming cycle. As a company, we are very proud that Queen Beatrix visited us.

2013

In 2013 we continued to apply precision farming applications. As a result, we started spreading variable compost using the scan made by the EM-38MKII. In our opinion this gives very good results.

On one of the last days of 2013, a machine was delivered by Dammann. Before 2014 this machine will spray our fields. We bought a self-propelled 3 axle 12000 liter syringe from Dammann. This syringe also has two tanks, so that we can also dose two means variably. Thanks to the three axles that the machine has, we can achieve an axle pressure of 8.5 tons, just like the Krampe tippers.

Vorige Volgende

Social media

Bezoekers online: 19